Newsletter 04/2024

Open day: You are cordially invited!

We will open our doors for you on September 12, 2024. Reserve the date today.

By moving into the new building, we have taken a big step into the future. We would like to take this opportunity to invite you to take a look behind the scenes of our company.

Date: Thursday, September 12, 2024

Time: From approx. 16.30

Location: Birren 20, 5703 Seon, Switzerland

The invitation with more information and the registration form will follow. We are already looking forward to your visit!

Best in class for the precise feeding of very small quantities

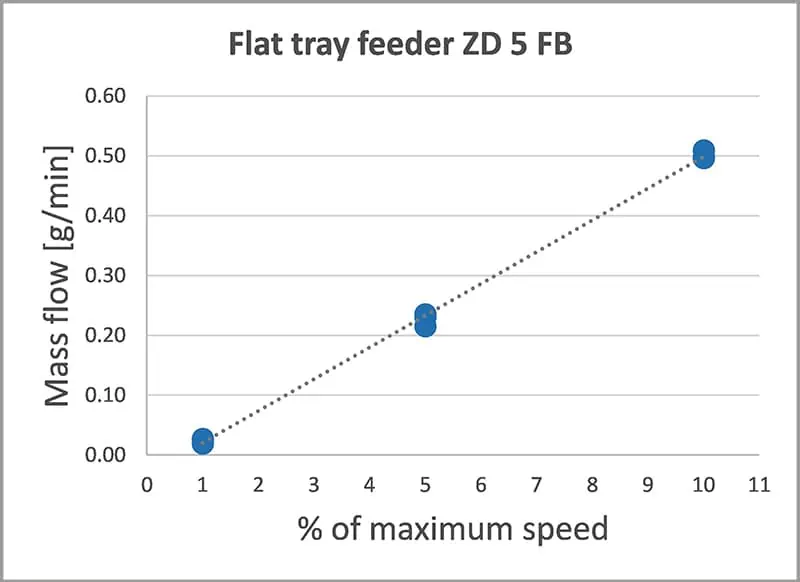

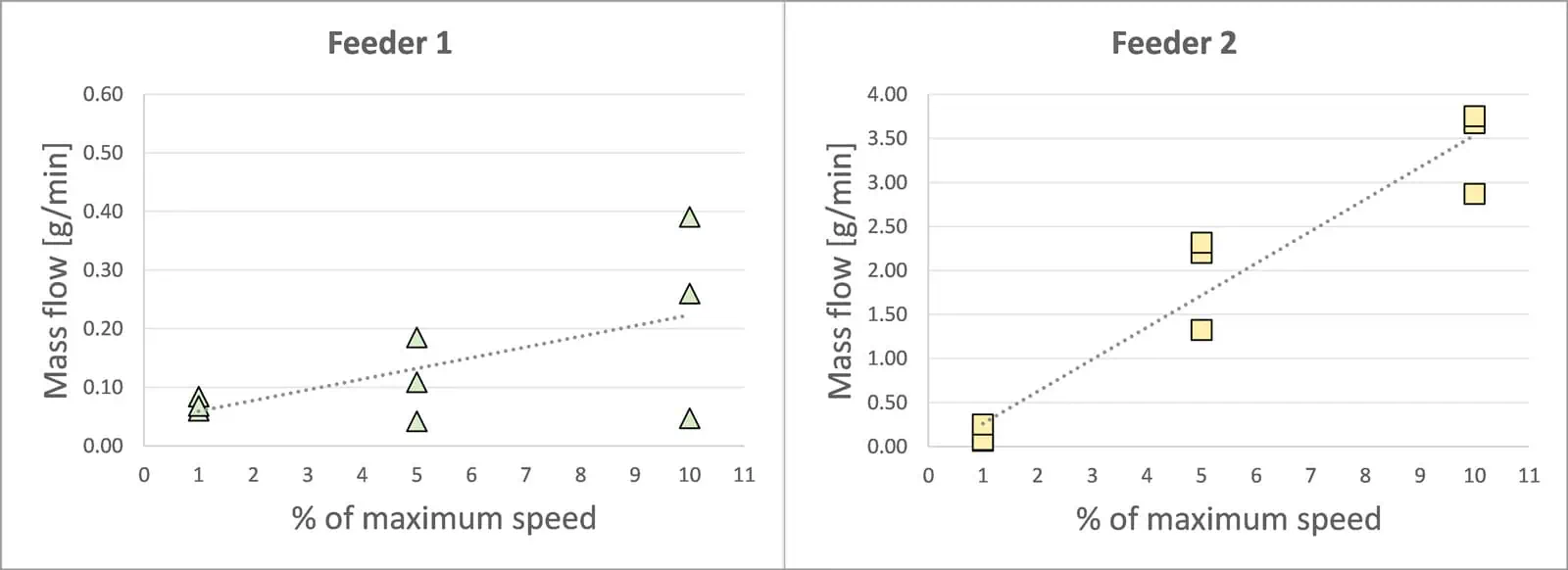

Handling heavy-flowing bulk materials places high demands on accuracy and reliability, especially when processing small quantities. In tests conducted by AMW, the ZD 5 FB feeding unit from Three-Tec proved to be particularly efficient.

For small quantities or feeding flows of less than 100 grams per hour, Three-Tec offers a reliable feeding solution with the ZD 5 FB flat-tray feeder. The smallest twin-screw flat-tray feeding unit in our range is ideal for feeding poorly flowing powders. With a screw diameter of just 5 mm, minimum feeding flows of 5 grams per hour can be achieved.

A high feeding consistency of the feeding device used is crucial for an accurate, continuous feeding result. If a high feeding consistency can already be achieved with a feeding device in volumetric feeding operation and without discharge or flow aids, only slight control interventions are required in gravimetric operation, which considerably increases the feeding accuracy.

AMW GmbH was looking for a feeding solution for quantities of less than 50 grams per hour. In tests with PLGA polymer powder using three feeding devices from different suppliers, AMW recorded three measuring points for each of three motor control commands. The feeding devices were operated purely volumetrically for the tests, i.e. without weight-based control.

The test results make it clear: The ZD 5 FB flat-tray feeder from Three-Tec outperformed other models in terms of low dispersion, making it the optimal choice for the most precise dispensing requirements.

AMW GmbH is an innovative bio-pharmaceutical company specializing in the development and manufacture of biodegradable drug delivery systems to improve therapy efficacy. With products such as goserelin and leuprorelin implants, AMW offers advanced treatment options for hormone-sensitive cancers. For more information visit the Website of AMW GmbH.

Current Projects

Most of our devices are developed and produced according to the specific requirements of our customers. We show you some of the devices and machinery that were completed and delivered last year.

ATEX-compliant, mobile powder feeding unit

Devices:

Flat-tray feeding unit ZD 22 FB with volumetric feeding, 10 liter hopper and 80 liter additional hopper

Industry/Use:

Powder feeding in the pharmaceutical sector, bulk density 0.2-0.6 kg/dm³, throughput 2.5-25 kg/h

Special feature:

- ATEX system: The control unit is within the ATEX area and therefore in a correspondingly pressure-encapsulated, certified control cabinet

- Volumetric or gravimetric feeding with control is part of a system and can communicate with the higher-level system control

- Device completely mobile as a push trolley

Extruder with innovative cooling roller

Devices:

ZE 32 extruder, ZD 22 FB flat-tray feeding unit, CRI 700 chill roller

Industry/Use:

Pharmaceutical production of medicinal products for human use

Special feature:

Innovative implementation of a cooling roller with a particularly long wrap angle. Thanks to our unique concept, even extrudates with a very high heat capacity or particularly high throughputs can be cooled many times more efficiently and with a comparably small device.

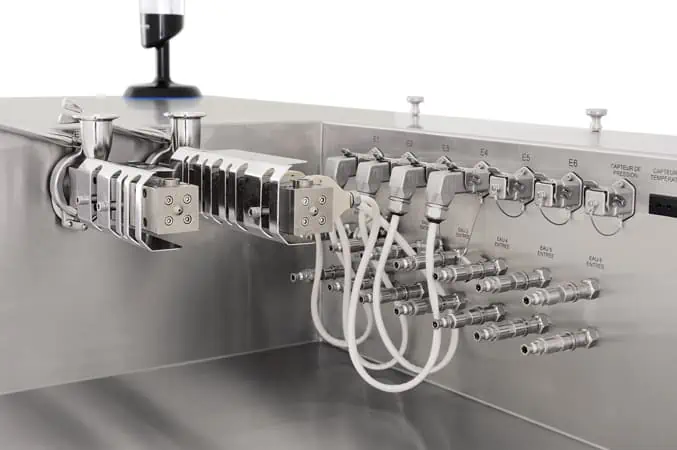

Hybrid extruder 9/12 HMI for the production of pharmaceuticals

Devices:

Hybrid extruder 9/12 HMI, two feeding devices ZD 9 FB, granulator HMI

Industry/Use:

Manufacture of pharmaceuticals

Special feature:

The medicines are produced in a clean room. The touch panel from Siemens has an integrated PC so that data recording of the process parameters and inputs can be carried out using an external control system.

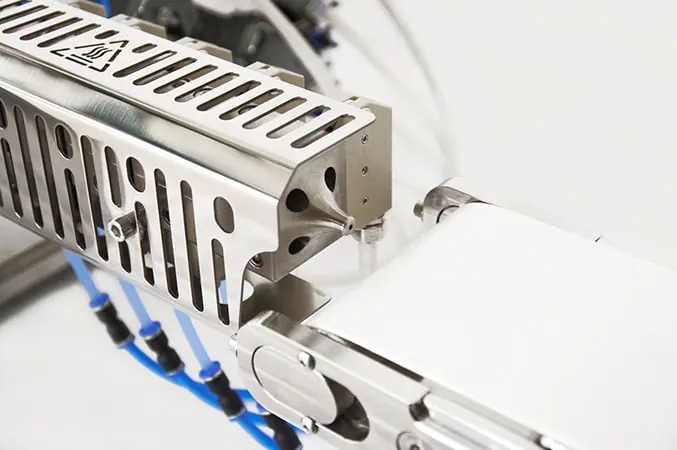

Extruder with cooling conveyor belt with integrated cutting unit

Devices:

ZE 12 HMI extruder, ED 12 single-screw feeding unit, cooling conveyor belt with integrated cutting unit

Industry/Use:

Luxury goods industry, production of ceramic rods

Special feature:

The extruded rods must have a density of 100% (no air inclusions or blowholes) and must not show any metallic abrasion. To achieve this, new materials were used for the barrel and extruder screws and a customized die design was developed. The conveyor belt and cutting unit were also developed specifically for this project.

Custom production of screw elements at short notice

Product:

Custom-made screw elements made of POM (polyoxymethylene) for use in a ZE 12 extruder

Industry/Use:

Research

Special feature:

We only had seven days from CAD modeling in the design department to internal production. In addition, the tool for the hexagon socket profile of the screw elements first had to be designed and manufactured in-house.

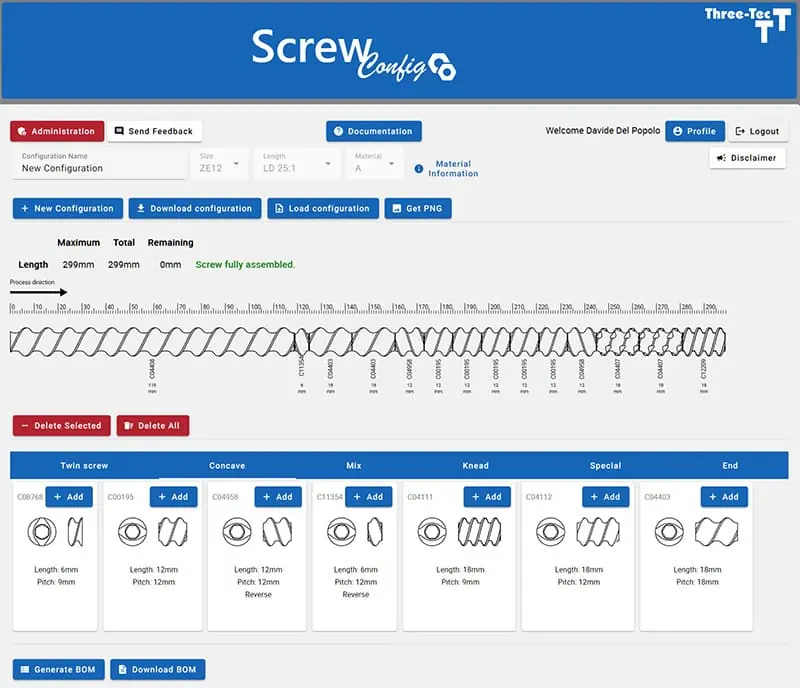

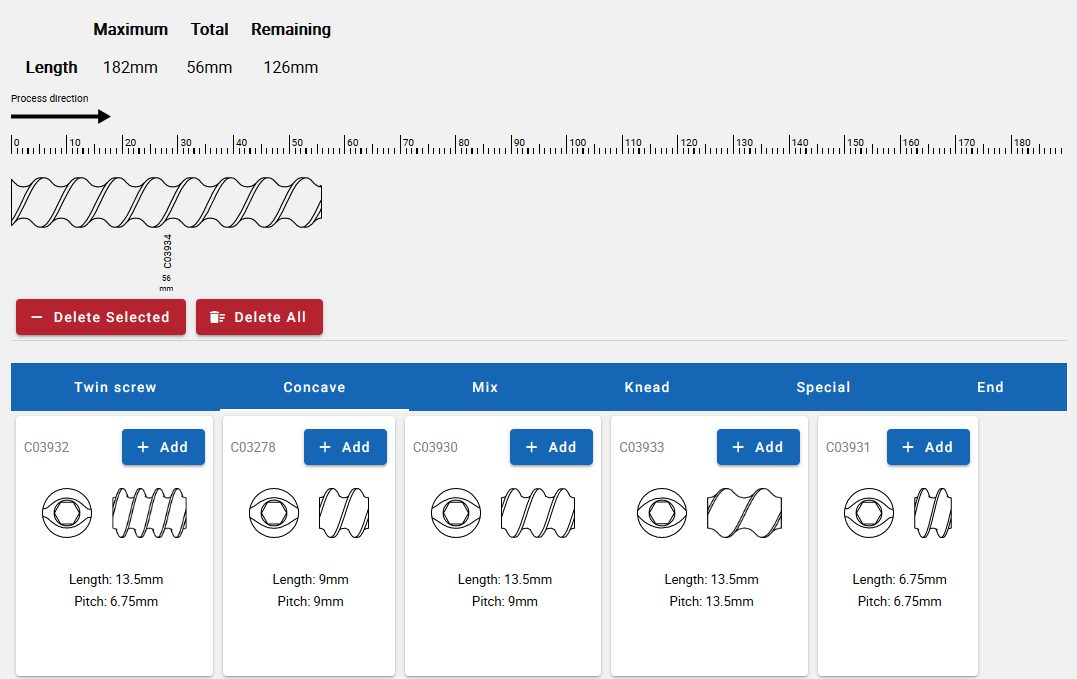

Simplified extruder screw design thanks to our screw configurator

Extruder screws and their configuration are of crucial importance for the quality and efficiency of production. With our in-house developed screw configuration software, the configuration of extruder screws is made considerably easier.

Extruders are indispensable in the processing of plastics, food, chemicals and many other products. The screw in the extruder plays a key role in this. Correct screw design is crucial to minimize material losses, ensure product quality and reduce energy costs.

Our web-based screw configuration software was developed and implemented from scratch in our company to make it easier for our customers to configure extruder screws. They can now configure their extruder screw designs in advance according to their requirements and order them directly, save them or use them for documentation purposes. The software not only offers an intuitive user interface, but also real-time visualization of the screw configuration.

If you would like to test the software or would like a consultation, please feel free to contact us:

Send e-mail