Extruders

With us you will find the right extruder for every application

Compact and user friendly

Laboratory and production extruder

ZE 5 laboratory extruder

ZE 9 laboratory extruder

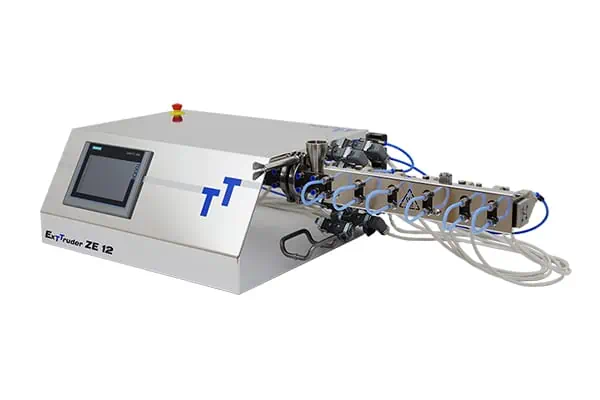

ZE 12 laboratory extruder

Hybrid laboratory extruder

ZE 18 production extruder

ZE 24 production extruder

ZE 32 production extruder

ZE 50 production extruder

ZE 50 detail view

The extruders from Three-Tec are characterized by a compact design, a high torque and a intuitive operation by means of a touch panel. They are available with various screw diameters from 5 to 100 mm and can process smallest quantities from 1 gram as well as large quantities up to 2 tons.

Our miniature laboratory extruders, which we have been developing and producing since 2005, are among the best in the industry. world's smallest devices. Through the compact and user-friendly construction the total cost per test is significantly lower than for other devices.

Special customer requirements can be realized at short notice thanks to Three-Tec's flexible approach and extensive know-how.

Highlights of our extruders

Screw diameter

Our extruders are available with different screw diameters and L:D ratios (15:1 to 50:1).

Rapid assembly or disassembly capability

Tri-clamp and bayonet connections enable a higher sample throughput.

Easy cleaning

The extruders are designed for easy cleaning and simple cleaning validation.

Temperature gradients

Steep temperature gradients between segments are possible due to cuts in the barrel.

Compact and lightweight

Due to their small size and light weight, the mini extruders are easy to transport.

Low active ingredient requirement

The mini extruders impress with their low active ingredient requirement and enable very small preparations.

Advantages

Multifunction extrusion from small quantities to production scale for research and development as well as production applications. Extrusion results are optimally suited for upscaling or downscaling. The extruders perform complex extrusion tasks under difficult conditions such as high pressure, high torque or steep temperature gradients.

All parts in contact with the product are made of stainless steel

Intuitive operation via touch panel, easy data output thanks to USB connectionIntuitive operation via touch panel, easy data output thanks to USB connection

Barrels can be produced completely according to customer requirements (heating and cooling zones, sensor technology, degassing, etc.)Barrels can be produced completely according to customer requirements (heating and cooling zones, sensor technology, degassing, etc.)

Simple barrel mounting with only one clamping ring that withstands very high loadsSimple barrel mounting with only one clamping ring, which nevertheless withstands high loads

A selection of the advantages of Three-Tec extruders:

Application areas

Discover the versatile application possibilities of our extruders.

Pharma

Food & Pet Food

Chemistry

Plastics

Contact

Are you interested in our extruders, do you have questions about them or would you like personal advice on extrusion?

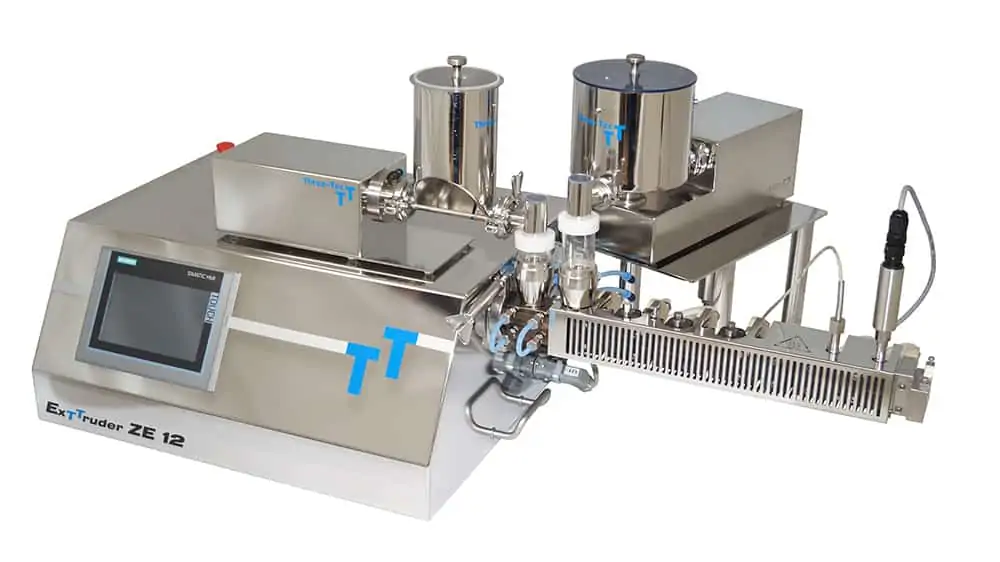

Hybrid laboratory extruder

The Hybrid laboratory extruder is built in the same housing as our proven standard extruder as a table-top version. As a combination device, however, it also offers the choice between two different extruder sizes. Three variations are available, each with a choice of two screw diameters (5, 9 or 12 mm).

During formulation development, often only small and often expensive quantities of active ingredients are available. On the other hand, many formulation trials are necessary to find an optimal formulation. These conditions require extrusion options on a resource-saving miniature scale. Three-Tec has developed a hybrid laboratory extruder for this purpose.

The parallel twin-screw laboratory extruder Hybrid features a Empty volume of only 1.2 cm3 with 5 mm screw diameter (L/D ratio 15:1) - the smallest of its kind in the world - has a very low consumption of active ingredients. This means that Small batches from as little as 1 gram is possible. Since only very small residual amounts remain in the extruder, a high yield can be achieved with the existing stock. Furthermore, the results can be optimally used for reproducible scaling.

Thanks to the universal use of heating cartridges, cooling systems, die plates, pressure and temperature sensors, the unit offers the flexibility to convert from a 5 mm to a 9 or 12 mm screw diameter within a few minutes. The range of applications is thus considerably enlarged compared to conventional extruders. within a few minutes from a 5 mm to a 9 or 12 mm screw diameter. The range of applications is thus considerably enlarged compared to conventional extruders.

Options and accessories

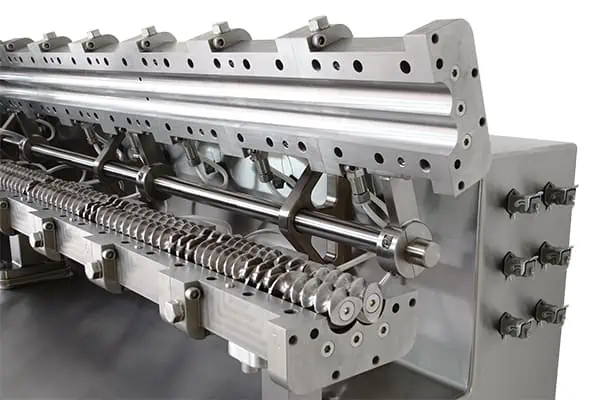

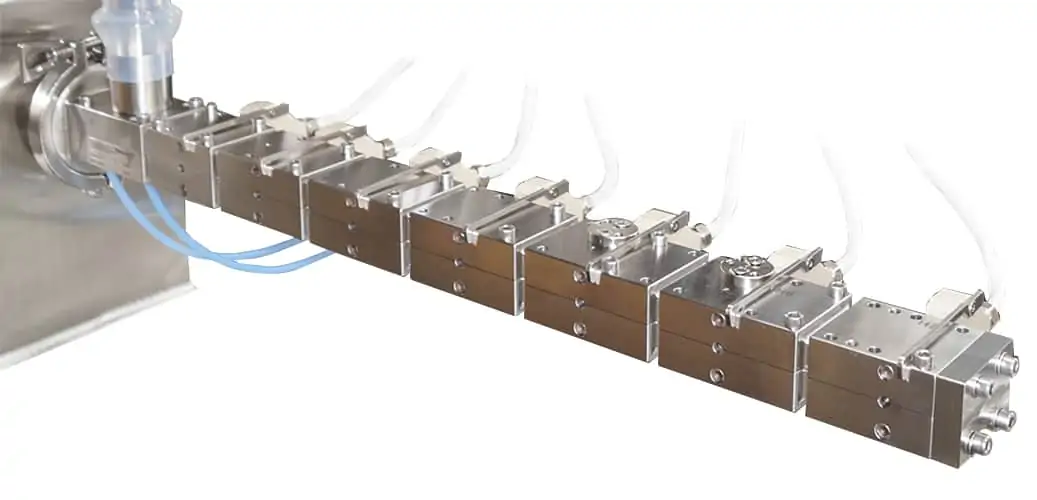

Extruder barrels are manufactured entirely in our own workshop. Customer requirements can thus be taken into account flexibly and easily.

Various liquid dosing points

Steep temperature gradient between heating zones due to deep milled grooveSteep temperature gradient between heating zones due to deep milled groove

Heating and cooling of individual zones possibleHeating and cooling of individual zones possible

Wide variation of nozzlesWide variation of nozzles

Easy mounting with only one clamping ring (Tri-Clamp)Easy mounting with only one clamping ring (Tri clamp)

Advantages of Three-Tec Extruder Barrels:

- Barrels can be completely modulated according to customer requirements and thus adapted extremely flexibly to a wide variety of process tasks: Heating and cooling zones, multifunctional metering inlets (solid, liquid, gas), sensors, degassing, etc.

- Barrel in one piece (completely tight for pressures > 200 bar) or split (split design for easy disassembly and cleaning)

- Different process lengths (L/D ratio) available and interchangeable at any time: 15:1 to 50:1 or according to customer requirements

- Combination of barrels with clamping rings possible

- Compact, weight-saving design: low energy consumption, fast heating and cooling times, easy assembly/disassembly

- Free-standing barrel offers dispensing and sensing capabilities from all four sides

Heating

The heating elements of the Three-Tec extruders can be mounted easily, quickly and without tools. Due to the high power and the large contact surface, an optimal temperature transfer and thus a fast heating takes place.

- Deep cuts between the individual heating zones allow for steep temperature gradients

- Number of heating zones according to customer requirements

- Efficient heating concept: uniform heating above and below the screws, enabling accurate temperature profiles and low energy consumption

- Individual temperature setting per heating zone

- Maximum temperature: 230 °C (optionally up to 400 °C)

Cooling

Cooling is performed per individual barrel zone. It is possible to operate the cooling manually or to regulate it via the extruder control system using solenoid valves.

Three different cooling modes are possible:

- Water cooling (manual or automatic)

- Air cooling (manual or automatic)

- Liquid nitrogen cooling (up to temperatures of minus 200 °C)

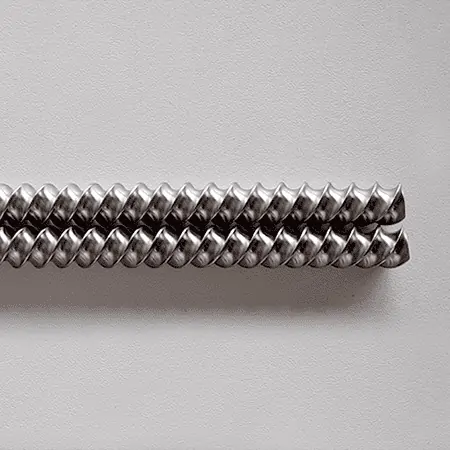

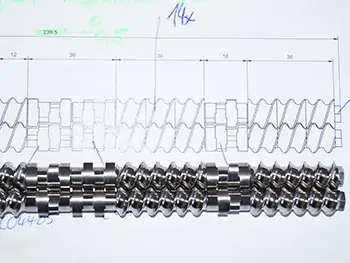

The extruder screws are configured to customer specifications on the basis of the process task and manufactured in the company's own workshop. This enables us to respond flexibly to customer requirements. A distinction is made between the following screw types:

-

Standard screws

in one piece; conveying only

-

Modular screws

interchangeable screw segments

-

Monobloc screws

demanding screw geometries, made from one piece

The fact that the monoblock screws are made from one piece significantly reduces the cleaning effort compared to modular screws, makes handling easier and improves strength.

In addition to the screw design (conveying segments, return segments, kneading segments with different angles, mixing segments, etc.), the extrusion performance also depends, among other things, on the temperature, metering capacity, material and flow properties, and die cross-section.

The advantages of our extruder screws:

- Screws in all sizes: 5 mm to 100 mm diameter

- Quick and easy assembly and disassembly of the screws as well as the screw segments

- Large selection of screw segments for conveying, kneading, compacting, stopping, relaxing and mixing

The extruder screws deliberately protrude into the die in order to be able to minimize the empty volume. This is particularly advantageous for formulation quantities with limited amounts of active ingredient.

Customized manufacturing

Elements for different processes

Screws from 5 up to 100 mm diameter

The dies are defined and manufactured according to customer and process requirements. Die diameters are possible from 0.1mm. The empty volume in the die is negligible, as the screws extend into the die until just before the opening.

Due to the simple design and low mass, separate die heating can be dispensed with in most cases. If heating of the die is nevertheless necessary, the same heating elements as for the barrel can be used for this purpose.

The following die geometries are possible:

- Single and double dies

- Sieve dies

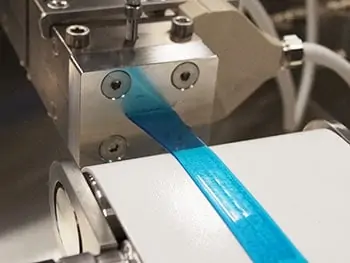

- Film dies (fixed or adjustable)

- Hose dies

- Cooling dies for meat substitutes

Standard dies

Sieve die

Film die

Hose die

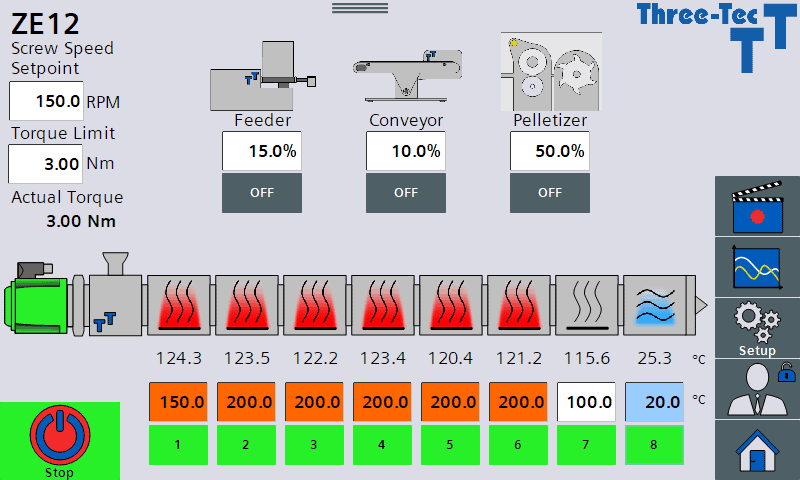

- Input of parameters via touch panel or alternatively via Ethernet connection

- Real-time monitoring of various process parameters possible (speed, torque, temperature of the individual heating zones, melt temperature, pressure in the barrel)

- Trend plot of process parameters

- Recording of process parameters

- Export of recorded data as CSV file via USB port

- Additional devices controllable (feeding, conveyor belt)

The result of an extrusion depends on many factors. So that you can achieve the best possible results, we offer you in our Test laboratory the perfect environment for all your needs. Test with your original products and our know-how. Either you visit us on site or we conduct the tests and you participate virtually via video conference. All tests are recorded photographically and on film and documented in writing.

Homogeneously colored extrudates

Flat extrudates

Sieve die plate with 50 orifices for efficient extrusion

Die for the production of hoses