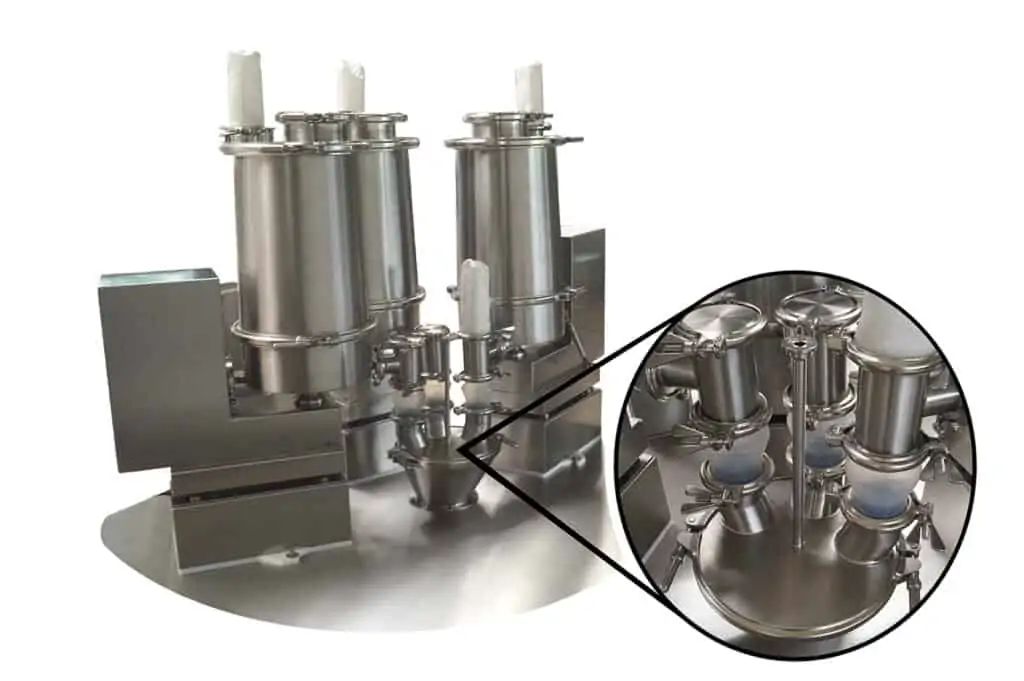

The modular multi-dosing system from Three-Tec is the perfect solution for accurate powder dosing of active pharmaceutical ingredients (API’s) and excipients in the solid dosage production process.

Up to eight different dosing units, each designed to specific product characteristics like feed rate, accuracy, and flow behavior, are modularly configurable according to customer requirements.

The multi-dosing system can be executed for continuous production processes with refilling units as well as for traditional batch procedures.

High-accurate dosing results, also with hardly flowing and cohesive powders, are essential for a repeatable process and further processing such as:

- Mixing / Blending

- Granulation

- Hot-melt extrusion

- Drying

- (Direct) compression

- Coating

Depending on the diameter and design of the screws, outputs from 0.005 kg/h up to 1,000 kg/h can be achieved.

The system is available as a stand-alone unit or as an integrable unit for the installation in an isolator.

Advantages:

- Maximal flexibility with 1 to 8 dosing units

- High-accuracy – Gravimetric loss-in-weight feeding with digital load cells

- Internal development: Flat-tray execution – The perfect solution also for hardly flowing products

- Pharmaceutical design – Simple and fast disassembly and cleaning

- Suitable for Wet-in-place (WIP) application

- Trials with custom products can be executed in the in-house test lab of Three-Tec